Main features

Flat and flexible silicone rubber heaters are made of fiberglass reinforced laminated silicone rubber sheets, vulcanized together through heat and high pressure on both sides of an embedded specially formed heating wire element. Fiberglass-reinforced silicone rubber gives the heater dimensional stability without sacrificing flexibility.

Silicone is used because of its high temperature resistance (Permanent temperature up to 200°C (390°F), high thermal conductivity (~7 10-4 W/cm.K) and good electrical insulation properties (~12KV/mm)

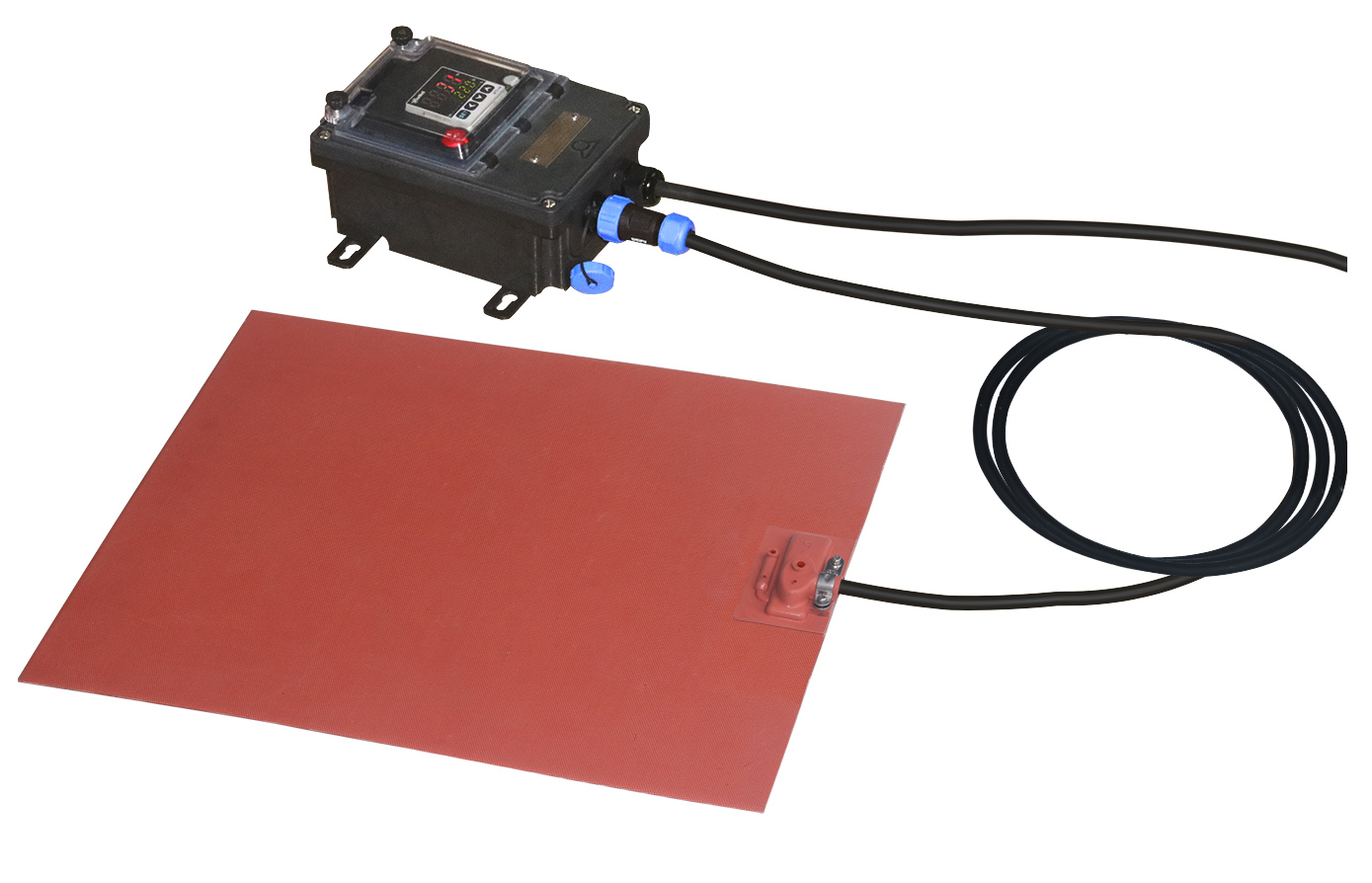

This series is distinguished by the use of a remote electronic control system, with PID action and automatic adjustment of parameters, with digital display of the measured value and digital display of the set point, connection by waterproof connector for easy disconnection of the heater, and IP65 ingress protection class for the whole assembly. This allows its use in most of industrial applications

Other general particularities of these heaters are:

- Not affected by vibration or flexing,

- Lightweight,

- Comply with UL94-VO (flame retardant) and ROHS,

- Low smoke and low Toxicity,

- Silicone is non-toxic, and moisture and chemical resistant

- Very thin profile

Main applications

Combining high surface power and flexibility, flexible silicone heating elements are a simple and economical solution for heating surfaces. They are light, thin, heat quickly and evenly because they are in direct contact with the surface to be heated. Their construction is rugged, and they do not change dimensions during heating. They can be mounted on flat or cylindrical surfaces. Their bonding to the surfaces can be made by vulcanization, room temperature vulcanizable resin (RTV), or by application of a pressure-sensitive adhesive (PSA).

Some typical examples of applications are:

Autoclaves, Surveillance cameras, Mold heaters for polymerization of resins, Poultry incubators, Diesel fuel filters, Defrost, Cash Machines, Laboratory Equipment, Gyroscopes, Laminators, Heated Mirrors, Animal Feeders, Photocopiers, Food heating Trays, Heat Presses, Battery Heaters, Tanks for liquids, etc.

They can be made in multiple shapes, receive cutouts or holes. They can receive temperature sensors, temperature limiters, thermal fuses and thermostats.

Mounting: By a pressing system on the surface made by the user or by bonding with a room temperature vulcanizing silicone resin (RTV), or by adhesive.

Length (Dimension A): Upon customer request

Width (dimension B): Upon customer request (minimum 100mm) Silicone foil minimum bending radius: 3.2mm (0.125)

Ingress protection: IP65.

Minimum ambient temperature: -10o C (+15o F)

Voltage: 220-240VAC.

Power tolerance: ±10% at 20°C

Temperature control: Controller with double display, of process value and of set-point, located in an independent waterproof housing, designed for wall mounting. It is connected to the flexible silicone rubber heater by a cable equipped with a 5-pin waterproof quick connector, facilitating the connection and disconnection with the heater. It controls the temperature by means of a probe placed under a silicone boot on the outer surface of the heater. Action: PID with automatic parameters adjustment by auto-tune function.

Sensor input: Pt100

Power output: solid state relay, maximum 16A 230V.

Alarm: 3A 230V relay.

Display: 4 digits display configurable in °C or °F

Power supply: AC 220-230V 50-60Hz.

Accuracy: ±1°C (±2°F) or 0.3% ES± one digit.

Self-testing: open sensor circuit.

Ambient temperature: -10 to 60°C, 20 to 85% relative humidity, non-condensing.

Temperature display range: Configurable

Resolution: 0.1°

Read instruction manual before the setting of this temperature controller.

Power density:

- 0.2 w/cm2 (1.3W/in²) for plastic materials

- 0.75 w/cm2 (4.8 w/inch2), for usual applications.

- 1 w/cm² (6.5 w/inch2) for fast heating applications

Other values on request.

Thickness of the flexible silicone foil:

- 1.6mm for light application and small surfaces

- 2.5mm for usual industrial applications

- 3.2mm, for heavy duty applications requiring strong mechanical strength and reinforced insulation.

Quality control routine tests: Each element is 100% tested for continuity, resistance and insulation. Tests are made according to EN 60335-1 and EN 50106 standards. See technical introduction.

Dielectric Strength: 1750V AC.

Insulation resistance: ≥ 10 Megohms.

Operating temperature:

See in the technical introduction examples of the temperatures reached by flexible silicone heaters. They represent the temperature that may reach the heating belt if it is not correctly installed.

Connection cable:

Insulated rubber power supply cable, for industrial environments, 3 x 1.5mm² (3xAWG15) length 3m, Euro plug. UL plug on request.

Options:

- Customer design shape, with or without holes

- Power supply 110/115V

- Power cord with industrial plug 2-pole + earth 16A CEE (IEC60309).

- Surface mounted temperature limiter.

- Surface mounted temperature sensor (Pt100, NTC, thermocouple)- Grounded mesh wire shield layer

- Silicone foam insulation layer vulcanized on the external surface

Safety standards:

The heaters have been designed in compliance with EEC Low Voltage Directive (LVD) 2006/95/EC and EMC directive 2004/108/EC. They must be installed in accordance with all local applicable instructions, codes, and regulations.