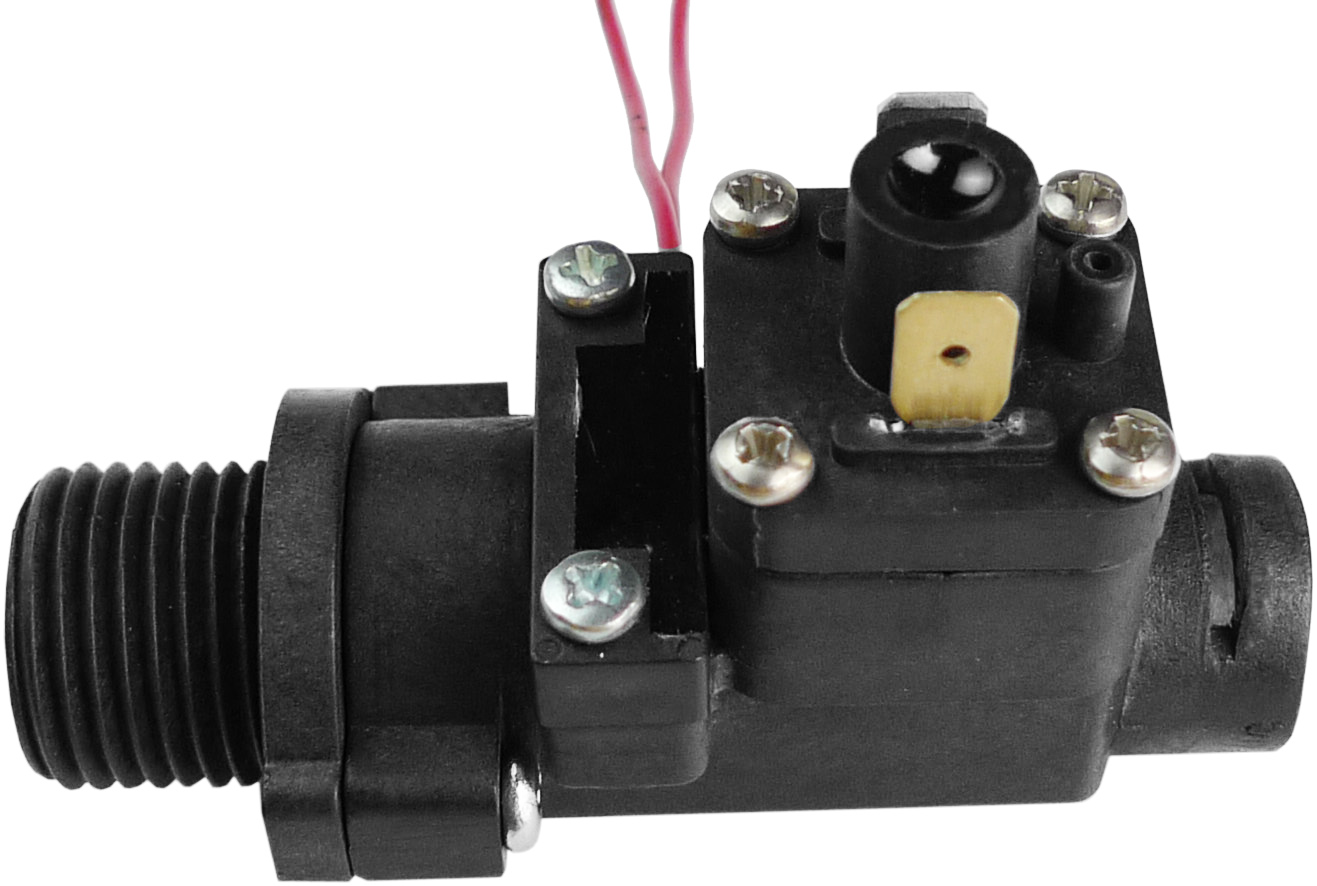

Main applications: Product developed for miniature instantaneous water heaters for showers in circuits where the water input pressure can be variable. The mobile flap system provides compactness. Water inlet is done directly by the ½" BSPP male thread. Mandatory vertical mounting, with water inlet from the bottom. Connection to internal copper piping DN8 and DN10 with quick coupling. A built in pressure switch will automatically stop water heating when the

water input pressure is lower than 800 millibar.

Functional principle: Magnetic flap mounted perpendicular to the flow and activating a reed switch through the wall. The return of the flap is made by gravity, without spring. No seal or liquid can pass between the piping system and the electrical contact. Suitable for potable water. Must not be used for water containing magnetic particles or high viscosity liquids, which block the movement of the pallet.

Adjustment: Can be factory set by adjusting the counterweight mounted in the flap

Body material: PPO compatible with drinking water.

Flap: PPO

Paddle shaft: stainless steel

Flow detection switch electrical rating: Max 1A, Max 70W, Max 250V, resistive load. Use on inductive circuits reduces electrical rating. We recommend to protect the reed switch with contact protection device when used in inductive loads

Flow detection electrical contact type: Normally open, closes by flow rise

Characteristics of the water inlet pressure switch:

1A 250V pressure switch, switches off the electrical heater when the inlet pressure decreases below 800 millibars, and switches on when the pressure is higher than this value. Electrical connection by two 6.3 × 0.8mm fast on terminals.

Liquids compatibility: For use with clean water and liquids without magnetic particles and without chemical incompatibility with PPO, stainless steel, and NBR pressure switch membrane

Nominal pressure at 20°C: 1MPa (PN10)

Flow detection set point factory setting limits:

Close by flow rise: 1.8 to 3 L/min

Open by flow decrease: About 0.4 to 0.5L/min lower than close value

Nominal diameter: DN8-DN10

Mandatory mounting position: on vertical pipes, upstream flow

Water pipe connection:

- Water inlet: on male ½" fitting with gasket with 2 anti-rotation lugs. Recommended torque 5N.m

- Water outlet: fast-on connection with O-ring and clips on DN8 or DN10 copper tubes with brazed or welded brass termination.

Liquids temperature range: 5 to 80°C

Ambient temperature range: 5 to 50°C

Ingress protection: IP65

Electrical connection: 2 × AWG24 wires (0.2mm²), PVC insulation, T80°, standard length 300 mm.

Accessories: brass terminations for brazing or soldering on other pipes diameters: see section 8 of this catalogue.

Options (MOQ apply): cable with connector or terminals, other cable length, other flow or temperature calibration values.

Important note: Standard copper tubes diameter for building applications (Water and gas) are given by the EN1057 standard, which defines the nominal diameter (DN) as the inside diameter. Copper tubes for applications in air conditioning and refrigeration are described in EN 12735-1 and those for vacuum and medical gases and vacuum are described in EN 13348. The EN127357 standard defines the copper tubes for refrigeration with diameters in inches. Copper tubes are often described in France by the outside diameter followed by the thickness in mm.