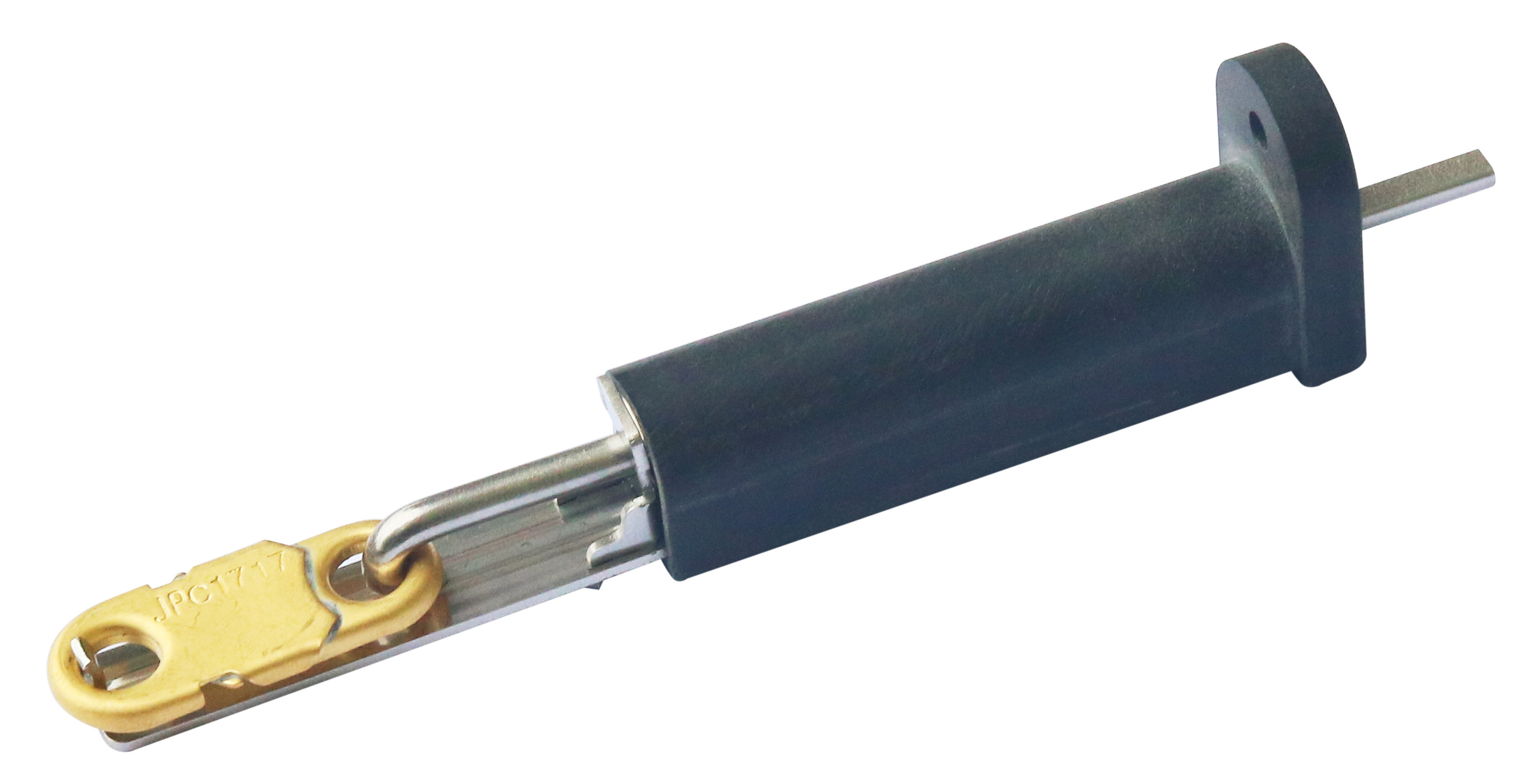

These mechanical thermal actuators are intended to close the fire dampers used on the ventilation ducts. Their large operating force unlocks the spring actuating the damper. Requiring no power supply, these devices are particularly simple and reliable. They are mandatory for all fire dampers to meet the NF-S 61.937 standard. The force they develop is compatible with eutectic alloy fusible links with a soldering surface equal to or greater than 200mm² *. However, some local regulations may require periodic replacement of the fuse link or the thermal actuator.

Length (A) of the actuating rod before release: 5, 10 or 15mm

(This length is given for a type 5EE fusible link with 23.8mm between holes axis, and varies proportionally to the fusible link holes axis distance).

Stroke of the actuating rod when triggering: ≥ 20 mm

Pushing force of the actuating rod: ≥ 15 DaN (at the beginning of the stroke).

Communication with the external environment: The mechanisms are equipped with a low leakage wall, separating the air of the ventilation duct from that of the external environment.

Installation: Through the wall of the ventilation duct, with M4 screws or self-tapping screws of similar dimensions. See the metal sheet cutting drawing above.

Body material: PA66 glass fiber reinforced, withstands temperature 200 ℃.

Mechanism material: Stainless steel Aisi 304.

ROHS compliance: These mechanisms are ROHS compliant, but the conformity of the assembly when fitted with fusible links depends on the conformity of the fusible link (See the technical data sheets of the fusible links).

Identification: Model and date of manufacture are stamped on each mechanism. When equipped with a fusible link, the link has its own identification (See the technical data sheets of the fusible links).

Salt spray resistance: According to ISO 9227-2012, subjected to a mist formed of 20% by weight of sodium chloride in distilled water, at 35°C for 5 days (120h), the mechanisms retain their aptitude for the function.

* The permanent mechanical strength of a eutectic fusible link depends on the soldering surface, but also on the composition of the alloy and the ambient temperature. See the limiting coefficients given in the technical introduction.